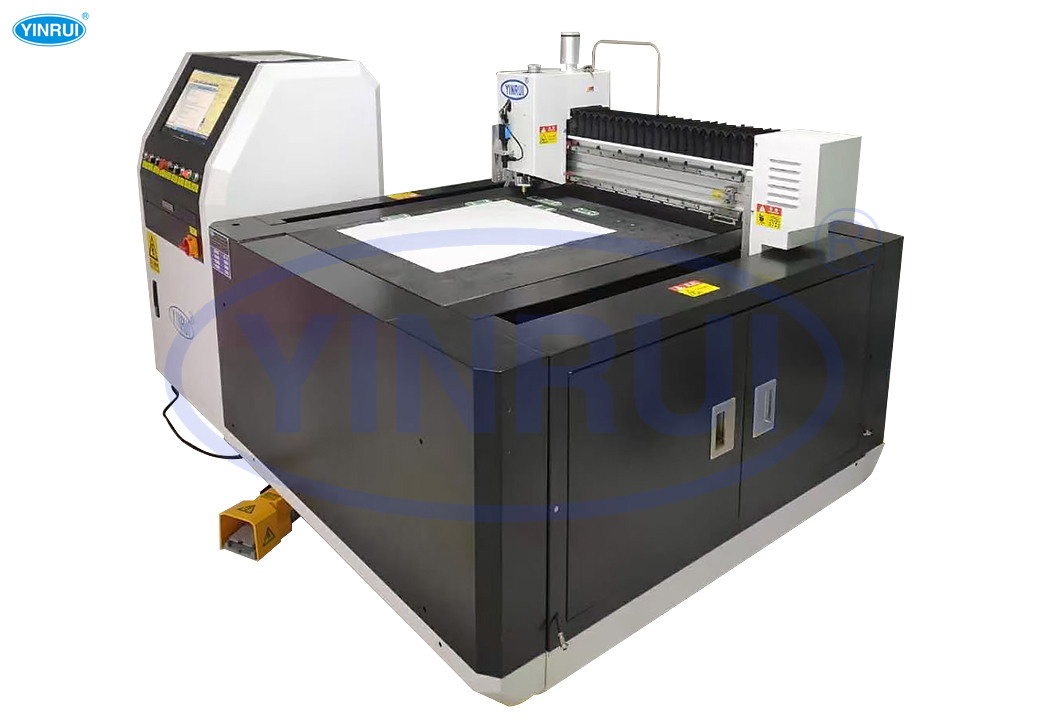

CNC Ultra-Thin Glass Cutting Machine YRDGZD500

1. Equipment technical parameters:

|

No.

|

Name

|

Technical specifications

|

|

1

|

Technical specifications

|

1900*1400 (including control box)*1350mm

|

|

2

|

Effective size of cutting glass

|

500*500mm

|

|

3

|

Minimum size of cutting glass

|

0.1mm

|

|

4

|

Cutting thickness

|

0.06-8mm

|

|

5

|

Straight line marking accuracy

|

±0.05mm

|

|

6

|

Special shape marking accuracy

|

±0.1mm--±0.15mm

|

|

7

|

Vertical accuracy of glass size

|

≤0.05℅

|

|

8

|

Plane accuracy of marble precision table

|

±0.005mm (electronic level detection)

|

|

9

|

Beam processing accuracy

|

±0.01mm

|

|

10

|

±0.01mm

|

0-50m/min

|

|

11

|

Total weight

|

1000KG

|

2. Equipment mechanical configuration:

|

No.

|

Name

|

Structural specification model

|

|

1

|

Transmission system (motor)

|

Inovance servo

|

|

2

|

Mechanical configuration (screw, guide rail)

|

Silver screw, guide rail

|

|

3

|

Cutting table

|

Precision marble table, air flotation device

|

|

4

|

Three-axis structure

|

Rotary servo motor

|

|

5

|

Oil supply method

|

Automatic oil filling device

|

|

6

|

Positioning device

|

Mechanical positioning device

|

3. Equipment electrical and gas configuration:

|

No.

|

Name

|

Specification model

|

|

1

|

Pneumatic components

|

Japan SMC

|

|

2

|

Electrical components

|

Taiwan Sanhe

|

|

3

|

Relay

|

Taiwan Taian

|

|

4

|

Proportional valve

|

Japan SMC

|

|

5

|

Filter, solenoid valve

|

Japan SMC

|

|

6

|

Switching power supply

|

Taiwan Mingwei

|

|

7

|

Button, indicator light, selection switch

|

Taiwan Sanhe

|

|

8

|

AC contactor

|

Taiwan Taian

|

|

9

|

Air switch

|

Taiwan Taian (with leakage protection function)

|

|

10

|

Bearing

|

Japan NSK

|

|

11

|

Computer configuration

|

ASUS

|

|

12

|

Power supply

|

380V

|

|

13

|

Air pressure

|

0.4-0.6MP (filter, dry air source)

|

|

14

|

Total power

|

Total power

|

4. Software system (made by Yinrui):

|

No.

|

Main function

|

|

1

|

The cutting origin position can be changed at will

|

|

2

|

The graphics can be automatically typed

|

|

3

|

Origin correction function

|

|

4

|

Typesetting and control are on the same software, which is quick and convenient to operate

|

|

5

|

Regional cutting can automatically optimize the tool path, and there are many optimization options

|

|

6

|

Automatic conversion of blowing and suction can be realized

|

|

7

|

Bidirectional cutting wheel deviation correction function

|

|

8

|

Pause function during cutting

|

|

9

|

360 sets of size memory function

|

|

10

|

Each piece of glass can be cut into 16 sizes

|

|

11

|

Size input error information report

|

|

12

|

Special shapes can automatically add dividing lines

|

5. Machine delivery list:

|

No.

|

Main accessories

|

|

1

|

3 sets of cutter heads (including: cutter wheel, cutter holder, small shaft), 1 set of copper sleeves

|

|

2

|

One set of debugging tools

|

|

3

|

One set of user manual (including software instructions and maintenance instructions)

|

|

4

|

One set of software backup

|

|

5

|

One set of system backup

|

6. Safety devices:

|

1

|

Design of safety mats

|

|

2

|

Configuration of safety gratings

|

|

3

|

Installation of safety guardrails

|

|

4

|

Limit protection

|

7. Machine after-sales service: two-year warranty, six-year precision warranty, lifetime maintenance (except for vulnerable parts anddamage caused by human or environmental factors), lifetime repair.

8. Spare parts list for cutting machine:

|

No.

|

Name of consumables required

|

Specification model

|

Quantity (specify the amount)

|

Replacement cycle

|

|

1

|

Cutter wheel

|

2.5*0.8*0.65*degree

|

One cutting machine 3--5 pieces/month

|

According to cutting length

|

|

2

|

Small shaft

|

0.8mm*4.2

|

Trial use

|

Trial use

|

|

3

|

Cutter clamp

|

Standard part ¢0.8mm

|

1 piece

|

1 piece

|

|

4

|

Copper sleeve

|

Standard part ¢8mm

|

1 piece

|

1 piece

|

|

5

|

Copper sleeve bearing

|

694Z

|

2 pieces

|

Trial use

|

|

6

|

Cutter head cylinder (airbag)

|

SMC 10S

|

1 set

|

1 year

|

|

7

|

Cutter head belt

|

Customized

|

1 piece

|

2-3 years

|

|

8

|

Proximity switch

|

8mm/12mm

|

6 pieces 12mm,1 piece 8mm

|

2-3 years

|

|

9

|

Yaskawa driver

|

400W

|

1 piece

|

Depending on the site environment

|

|

10

|

Yaskawa driver

|

850W

|

Two pieces

|

Depending on the site environment

|

|

11

|

Y-axis belt

|

/

|

2 pieces

|

3 years-5 years

|

|

12

|

X-axis screw

|

/

|

1 piece

|

Test use frequency

|

|

13

|

Y-axis screw

|

/

|

2 pieces

|

Test use frequency

|

|

14

|

Proportional valve

|

2050

|

One piece

|

Test use frequency

|

|

15

|

Breaking table felt

|

/

|

1

|

1 year-3 years

|

9. Consumables list:

|

1

|

Cutter wheel

|

2.5*0.8*0.65*degree

|

One cutting machine 3--5 pieces/month

|

According to cutting length

|

|

2

|

Small shaft

|

0.8mm*4.2

|

Trial use

|

Trial use

|

|

3

|

Cutter clamp

|

Standard part ¢0.8mm

|

1 piece

|

Trial use

|

|

4

|

Copper sleeve

|

Standard part ¢8mm

|

1 piece

|

Trial use

|

|

5

|

Copper sleeve bearing

|

694Z

|

2 pieces

|

Trial use

|

|

6

|

Cutter head cylinder (airbag)

|

SMC 10S

|

1 set

|

1 year

|

|

7

|

Cutter head belt

|

Customized

|

1 piece

|

2-3 years

|

Previous Next