|

|

|

PRODUCTS PRODUCTS |

|

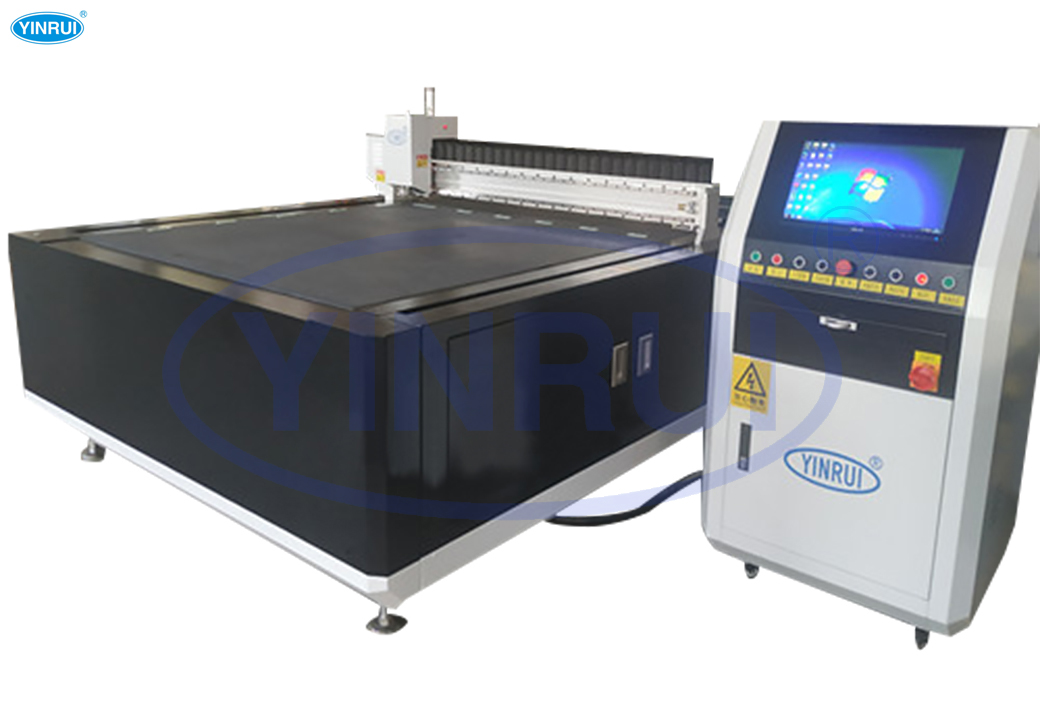

CNC Ultra-Thin Glass Cutting Machine

1. Technical Parameters:

-

Cutting Thickness: 0.15–8 mm

-

Overall Dimensions: 2100 × 1750 × 1500 mm

-

Effective Size of Cutting Glass: 1300 × 1100 mm

-

Machine Weight: 1800 kg

-

Straight Line Cutting Tolerance: ±0.05 mm

-

Marble Precision Table Surface: ±0.015 mm

-

Cutting Speed: 0–70 m/min (adjustable)

-

Voltage: 3-phase 380 V

-

Power: 3.1 kW

2. Main Configuration:

-

Transmission System: X, Y, and Z axes use Huichuan servo motors

-

Mechanical Configuration: Screw rod and guide rail are from Taiwan Hiwin

-

Table: Marble precision table, including an air flotation device

-

Oil Supply Method: Automatic oil filling device

-

Positioning Device: Mechanical positioning device

-

Bearing: NSK

3. Electrical Components:

-

Air Switch: Taiwan Taian (with leakage protection function)

-

AC Contactor: Taiwan Taian

-

Button, Indicator Light, Selector Switch: Japan Izumi

-

Switching Power Supply: Omron

-

Relay: Omron

-

Proportional Valve: SMC

-

Filter, Solenoid Valve: SMC

-

Computer: Asus

4. Software System (Made by Yinrui):

-

Uses professional glass cutting software and CAD drawings to cut rectangles and various graphics.

-

The cutting origin position can be changed freely.

-

Includes an origin correction function.

-

The layout function offers many standard patterns.

-

Multi-area cutting can automatically optimize the tool path, with several optimization options (default cutting uses the optimal path).

-

Supports the conversion of blowing and suction (controlled by a foot switch).

-

Includes a pause function during cutting.

-

Features 360 sets of size memory.

-

Each piece of glass can be cut into up to 16 sizes. The software allows for 10 sizes in the area cutting setting, while CAD drawings can support additional sizes.

-

Displays information about size input errors.

-

Includes a cutting quantity function (daily and monthly production counts): records the total number of pieces, without distinguishing between daily and monthly counts.

-

Cutting method: manual setting function.

5. Delivery List:

-

1 glass breaking table

-

1 set of cutter heads (including cutter wheel, cutter holder, and small shaft), 1 copper sleeve

-

1 set of debugging tools

-

1 software backup

-

1 system backup

-

1 user manual (including software instructions and maintenance instructions)

6. The Buyer Needs to Provide:

-

Power Supply: 3-phase 380V (3 live wires, 1 neutral wire, 1 ground wire)

-

Air Source: 0.4–0.6 MPa dry air (external φ8 mm air pipe)

-

After-Sales Service: One-year warranty (excluding vulnerable parts and damage caused by human error or environmental factors), lifelong maintenance.

-

List of Vulnerable Parts: Cutter wheel, cutter clamp, copper sleeve, cutter shaft, bearing, cylinder, synchronous belt, etc.

Previous Next

|

|

|

|

|

Add: No.4 Xinya Road, Dalingya, Daojiao Town,Dongguan City, Guangdong Province, China Zip Code: 523183

Tel: +86-769-88319361 81331281 Fax: +86-769-88319365銆€

After-sales Services Tel: +86-769-81331280

General manager錛歁s.Zhu +8613829263778 Website: www.bdbwg.com

Email: zhuxj@dgyinruijixie.com

MSN錛歞gyinrui@hotmail.com

Guangdong Dongguan Yinrui Precision Machinery Co., Ltd All Rights Reserved 綺CP澶?7024712鍙?1 Technology Supporting: glassinchina.com

|

|